LABORATORIES

Software details

Our department features well-equipped laboratories that support both curriculum requirements and advanced learning.

-

Aerodynamics Lab

-

Gas Dynamics Lab

-

Aerospace Structures Lab

-

Aerospace Manufacturing Technology Lab

-

Computational Mechanics Lab

-

Aerospace Propulsion Lab

-

Aircraft Instrumentation Lab

Aerodynamics Lab

Faculty In-charge:

Prof. Srinivasan S

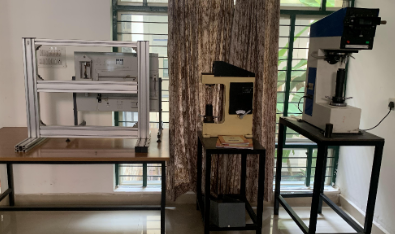

The Aerodynamics Lab at RVCE houses a state-of-the-art Low Speed Subsonic Wind Tunnel, serving as a vital experimental facility for both undergraduate and research activities in Aerospace Engineering. This wind tunnel enables precise aerodynamic testing and flow visualisation over a wide range of velocities, supporting studies in airfoil and wing performance, boundary layer development and aerodynamic force measurements. The high contraction ratio and honeycomb section ensure uniform and low-turbulence airflow, providing reliable data for both academic and applied research. The facility is integral to the department’s hands-on learning approach, allowing students to design, fabricate and test models under real-world conditions. It also supports faculty and student research projects, industry consultancy and collaborative innovation in aerodynamics and related fields. The important specifications of the low-speed wind tunnel are given:

Low Speed Subsonic Wind Tunnel

![]()

Type of Wind Tunnel: Open Circuit Suction Tunnel

![]()

Test Section Size: 600mm X 600mm X 2000mm

![]()

Maximum Speed: 80 mtr/sec

![]()

Contraction Ratio: 9:1

![]()

Honey Comb L/D: 8

Gas Dynamics Lab

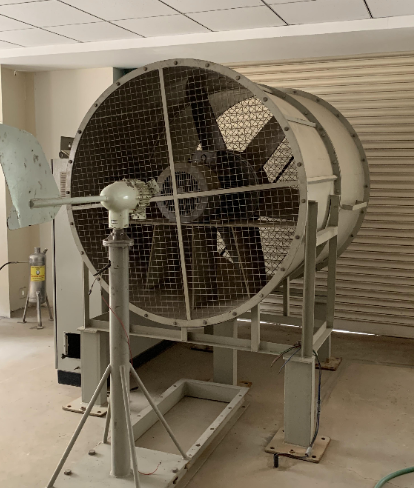

The Gas Dynamics Lab is equipped with a modern Blowdown Supersonic Wind Tunnel designed to facilitate fundamental and advanced studies in compressible flow and high-speed aerodynamics. This laboratory-scale wind tunnel provides a controlled environment for investigating supersonic flow phenomena, shock waves, expansion fans and aerodynamic characteristics of models at high Mach numbers. The blowdown design allows for efficient, intermittent operation using stored compressed air, closely mirroring industry-standard testing practices for supersonic regimes. The facility’s data acquisition system enables real-time monitoring of pressure distributions within the test section, supporting both educational experiments and research in gas dynamics. The availability of multiple interchangeable nozzles allows students and researchers to explore a range of supersonic conditions, making the lab a valuable resource for understanding the complexities of high-speed aerodynamics. Through hands-on experimentation and analysis, the Gas Dynamics Lab empowers students to bridge theoretical knowledge with practical skills, preparing them for careers in aerospace research, design and innovation.

Supersonic Wind Tunnel

![]()

Type of Wind Tunnel: Blowdown Supersonic Tunnel

![]()

Test Section Size: 100*100mm

![]()

Maximum Speed: 1.5-3.5 Mach

![]()

Screw Compressor: 300psi

![]()

DAQ: 16 Channel Electronic Pressure Scanner

![]()

Pneumatic Pressure Regulating Valve: 1 No

![]()

Storage Tank: 500 cft at 300 psi Pressure with Safety Valve

![]()

Nozzles: FRP 4 Nos for Mach (1.5,2,2.5 & 3.0)

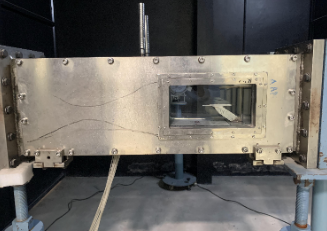

Aerospace Structures Lab

Faculty In-charge:

Dr. Benjamin Rohit R

The Aerospace Structures Lab is a cornerstone facility for the study and analysis of structural behaviour in aerospace materials and components. The lab is equipped with advanced instrumentation to support both instructional and research activities in the field of aerospace structures.

![]()

Strain Gauge Trainer Kit:

Enables students to gain hands-on experience in measuring strain and understanding stress distribution in structural elements. This kit is essential for experiments related to material deformation, load response and validation of theoretical models.

![]()

250 kN Universal Testing Machine (UTM) with High Cycle Fatigue (HCF) Capabilities:

This state-of-the-art testing machine allows for comprehensive testing of aerospace materials and components under various loading conditions. With a maximum capacity of 250 kN, the UTM supports tensile, compressive and flexural testing as well as fatigue testing to simulate real-world operational stresses encountered by aerospace structures.

The lab provides a robust platform for students to bridge the gap between theory and practice, enabling them to conduct experiments on material properties, structural integrity and failure mechanisms. Under the guidance of experienced faculty, students develop critical skills in experimental techniques, data analysis and structural assessment, preparing them for careers in aerospace engineering and research.

Aerospace Manufacturing Technology Lab

Faculty In-charge:

Prof. Pranesh Kumar S R

Computational Mechanics Lab

Faculty In-charge:

Prof. Bhaskar K

The Computational Mechanics Lab facility empowers students and researchers with advanced computational tools for modelling, simulation and analysis in Aerospace Engineering. The lab is equipped with 66 high-end desktops providing ample resources for complex computational tasks and collaborative projects. The Computational Mechanics Lab serves as a vital hub for coursework, research and industry-sponsored projects. It enables students to develop expertise in computer-aided design, structural analysis and simulation-driven engineering, ensuring they are well-prepared for the demands of the aerospace industry and advanced research.

![]()

Industry-Standard Software Packages:

Students and faculty have access to a comprehensive suite of professional software, including:

- ANSYS: For finite element analysis and multiphysics simulations

- MATLAB: For mathematical modelling, data analysis and algorithm development

- MSC NASTRAN: For advanced structural analysis and aerospace simulations

- CREO Parametrics: For 3D CAD design and product development

- Dassault SOLIDWORKS: For mechanical design and simulation

Aerospace Propulsion Lab

Faculty In-charge:

Dr R Supreeth

The Aerospace Propulsion Lab is a premier facility dedicated to the study and experimentation of propulsion systems fundamental to aerospace engineering. The lab provides students and researchers with hands-on experience in understanding the principles and performance of various propulsion technologies. The Aerospace Propulsion Lab’s advanced infrastructure supports a wide range of experiments, from fundamental aerodynamic investigations to applied propulsion system testing. Under the guidance of expert faculty, students gain invaluable practical insights into the operation and analysis of aerospace propulsion systems, preparing them for careers in both industry and research.

Freejet Facility

![]()

Reservoir pressure: 1- 5 Bar

![]()

Airflow duration: 2-3 minutes (Depending on pressure)

![]()

Instrumentation: 3 Axis Traverse with pressure probes

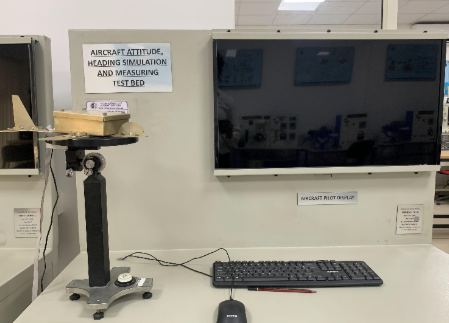

Aircraft Instrumentation Lab

Faculty In Charge:

Group Captain Prof Deepak Bana

Research

Industry Sponsored Projects

Consultancy

Address:

RV College of Engineering, RV Vidyanikethan Post, Mysuru Road, Bengaluru – 560 059

Principal’s Office

Dr. K.N. Subramanya

Principal

RV College of Engineering

Phone no:

+91-080-68188100 / 8111

principal@rvce.edu.in